Mechanical Set Cement Retainer

WPCR Cement Retainer (Wireline Set)

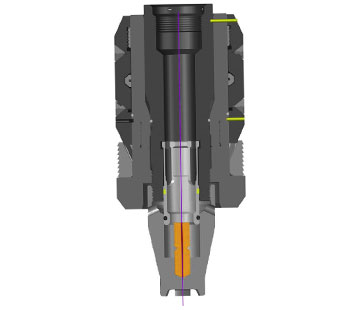

DIC WPCR Cement Retainer is a wireline set, high-pressure retainer constructed of drillable gray cast iron. WPCR is set on baker 10 or baker 20 pressure setting tools (PST) on wireline/e-line.

DIC WPCR can also be set on tubing/drill pipe/coil tubing using a hydraulic setting tool. Opposing slips are carburized wicker type. One piece slips are located above or below the rubber packing element.

The packing elements are contained by brass backup rings that eliminate the extrusion of the elements at high temperatures and pressures. WPCR utilizes a wireline adapter kit to connect to baker PST and run in a hole. Once set, a stringer is run on tubing/drill pipe/coil tubing in the second trip and stung into the WPCR cement retainer. Squeeze operation can begin now and the operator controls the two way valve from the surface to hold, final squeeze pressure under retainer and test tubing, or keep hydrostatic pressure off the squeeze manipulating the stringer assembly.

Straight pick up closes the valve, or set down weight opens the valve. This retainer is perfect for where squeeze cementing operations are being performed. Standard packing element is Nitrile (70 Duro). Optional packing systems or Aflas are available on special orders.

Stinger Assembly:

DIC Stinger Assembly is a tubing conveyed latching seal assembly used to operate the sliding valve in a wireline set WPCR cement retainer. The stringer assembly may be run with a tubing centralizer or a modified star guide to provide a centralized entry into the cement retainer. The snap-in and snap-out collet serve as an indicator. Providing positive control when the work string picked up to close the slide valve. The snap-out indicator may be removed from the cement retainer by straight pull or rotation, serving additional safety features.

- Squeeze cementing.

- Multiple uses by replacing inexpensive redress kit.

- It can also be used with preset PCR mechanical cement retainers.

Stinger Assembly Benefits: